- Home

- About

- Our Solutions

- FTTX,GPON & EPON

- Wireless, Hotspot & Radius

- Structured Cabling

- Computers and Servers

- Storage and Cloud

- Routing and Networking

- CCTV & IP Surveillance

- Automation, Access & Control

- Digital Display and Signages

- IPPBX, VOIP & Phones

- Pro Sounds & Lighting

- Public Address & Audio Paging

- Security Firewall

- Smart Home

- Solar & Power Backup

- Products

- Trainings

- Services

- News

- My Account

- Contact Us

WELCOME TO ACOM TOOLS

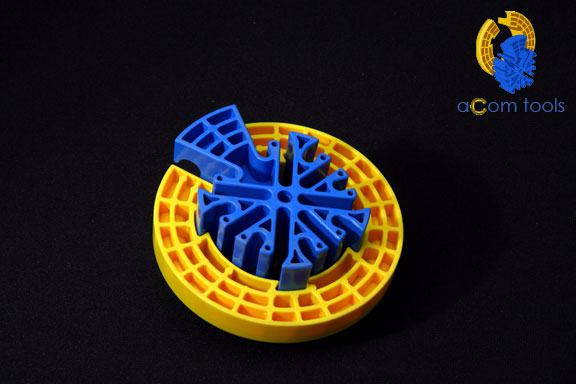

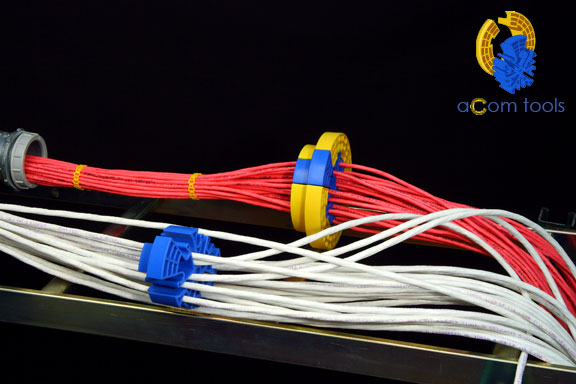

The Cable Comb ™ (U.S. Patent 6,976,512 B2) substantially cuts labor time in any application where a multitude of single cables must be bundled neatly for a professional appearing installation. This innovative two piece tool enables cable technicians to quickly and efficiently straighten, organize, and lash single cables into multiple cable bundles with ease.

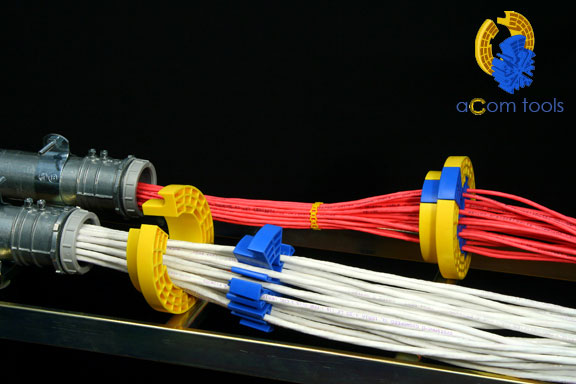

Individual cables are loaded into the open slots of Cable Comb’s blue inner hub at any point within the run without the need to find and thread cable ends through closed holes. The yellow outer collar is mated to the blue inner hub after the cables are loaded into the slots. This prevents cable dislodgement from the tool until the outer collar is removed. Removal of individual or groups of cables for termination, direction changes, or sub bundles is easily accomplished by sliding the yellow outer collar back a few inches from the blue inner hub and removing the selected cables through the large opening in the collar. The two piece tool can then be mated again to continue the combing process. Due to the unique design of the Cable Comb all cables are combed into an organized bundle, not just the outer cables.

The Cable Comb hub has been designed with 15 cable slots. Each slot will accommodate various types and quantities of category cable including most CAT 5, CAT 5E and CAT 6 cables. The Cable Combcan also be used to straighten, organize, bundle, and lash other types of cables such as plenum, co-axial, and control cable in sizes ¼” or smaller. The cable slots are chamfered to help prevent snagging of looser fitting cable jackets.

With the convenient built in concave finger pull the Cable Comb can be installed in any position allowing for smooth and comfortable pulling without worrying about orientation of the tool or interference with protruding handles.

The Cable Comb slides easily on the cable as it is manufactured by injection molding with Zytel® nylon resin and has a naturally slick feel which provides for a low friction surface on the slots. The Zytel® nylon resists penetration of oils, greases, solvents, and alkalis and makes the Cable Combdurable and long lasting.

The Cable Comb from Acom Tools will benefit both contractors and technicians by saving time whenever the labor intensive task of organizing individual cables into professional appearing bundles is required.

CABLE COMB IMAGES

CABLE COMB INSTRUCTIONS

The ‘Cable Comb’™ from Acom Tools consists of a blue inner hub and a yellow outer collar. The inner hub is designed to interlock with the outer collar to provide an assembly allowing installers to conveniently straighten, organize, and lash single cables into professional appearing cable bundles. The open slots of the inner hub and the split opening of the outer collar allow the cables to be loaded or removed from the tool at any point within the run without threading the ends of cables through closed holes.

- Arrange the cables to be bundled into kink-free runs.

- Hold the blue hub perpendicular to the run of the cables to be combed with the rounded finger pull of the pie-shaped protrusion (the back of the tool) opposite the direction the tool will be pulled.

- Load the individual cables into the various slots of the blue hub. The cable fill of each slot will depend on the type of cable being combed. Do not overload a slot with cables. Cables in each slot must remain loose after assembly of the outer collar.

- Once the cables are loaded in the blue hub, slip the yellow collar over the cables at the back side of the blue hub.

- Rotate the collar to align the pie-shaped protrusion of the hub to the opening on the collar and slide the collar onto the hub.

- Begin sliding the Cable Comb hub and collar assembly down the cable length. The cables emerge from the wire comb in an organized bundle.

- Secure and wrap the combed bundle with Velcro, tie wrap, or equivalent cable lash every 2 to 3 feet as desired to maintain bundle integrity. Continue the combing process to provide bundle lengths as required for the installation.

- If necessary, disengage the yellow collar from blue hub to unload individual cables which need to be removed from the bundle for termination, or, to remove groups of cables for sub bundles. Slip the yellow collar back onto the blue hub to continue combing.

- To remove the Cable Comb, disengage the yellow collar and remove it from the group of cables being bundled and unload remaining cables from the blue hub. The Cable Comb may also be slid completely off the end of the remaining cables to remove the tool as mated assembly.

- Keep the inner blue hub mated with the yellow outer collar during storage to protect the slots and face of the tool from potential damage.